Hydraulic Resource is located in Bellevue, Western Australia and is a distributor of GPM hydraulic pumps.

24 Years of Excellence

Hydraulic Resource has been highly successful in meeting customers’ demands and has become recognised for its expertise in supplying new and re-manufactured hydraulic components.

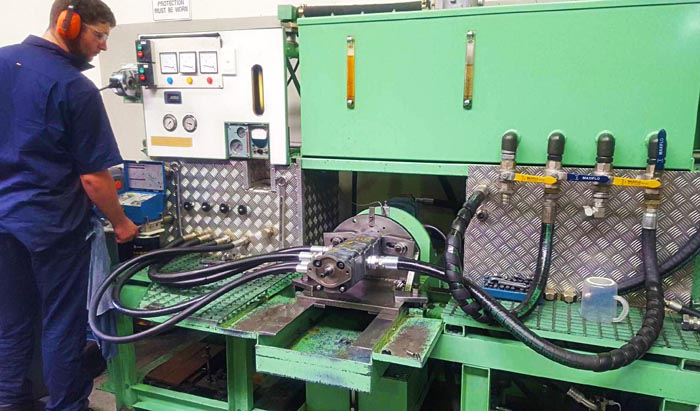

Our facility is a modern purpose-built workshop staffed by a team of dedicated and experienced technicians.

Technology

We work closely with:

- Gear Pump Manufacturing (GPM), our manufacturing partner in Cape Town, South Africa

- GPM US, GPM’s distribution facility in the USA

Through these relationships and our training and retention of world-class expertise, we are equipped to ensure the best and latest technology is available to customers.

Products

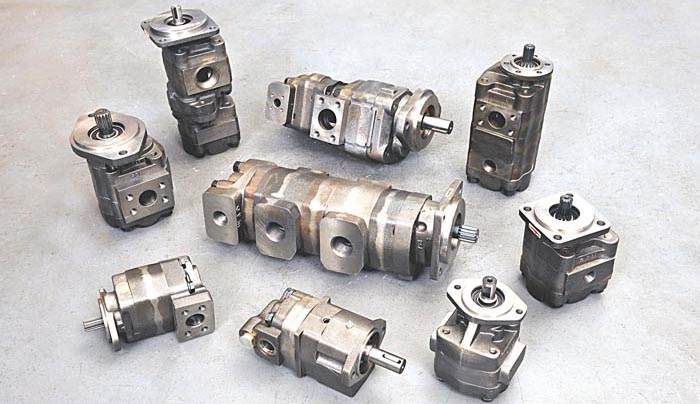

The products displayed on this site are summarised in the following product ranges:

- Hydraulic Bearing Gear Pumps

- Hydraulic Bushing Gear Pumps

- Hydraulic PTO Bearing Pumps

- Flow Dividers

- Add-a Pumps

- Step-Down Pumps

- Replacement Parts

Inventory

- GPM assemblies

- Commercial (Parker)

- Permco

- Metaris

Manufacturing and Repair Capabilities

These capabilities, combined with an extensive range of components held in stock, allows Hydraulic Resource to offer a fast and efficient turn-around of new and remanufactured units at short notice, thus allowing customers to keep their downtime to a minimum.

All assemblies are fully tested on a purpose built test facility, powered by a 45kW electric motor driving a hydrastatic transmission.

Because of these unique manufacturing techniques, pumps and motors can be made to replace many original equipment units utilised on local and imported machinery. Sometimes these OEM units may be difficult to source or can be very expensive. Our expertise can be used to replace these pumps and motors in a timely and cost effective manner.

Why GPM Products are Superior

The keys to the long life and superior operation of GPM products are in their casings, gears and shafts which are made of the most advanced materials.

Established in February 2002, the foundry is equipped to produce Grey Iron, SG Iron, and Compacted Graphite Iron (CGI) materials, along with bronze cast components which are assembled in a wide variety of configurations to suit almost any application. The superior metallurgical structured CGI material is used in the manufacture of the higher pressure requirements of the Bushing Pump Range.

Environmental responsibility is integral to its operations. To minimize waste and costs, GPM has invested in a swarf pelletizing machine. This innovation transforms iron and steel swarf, along with factory offcuts, into recyclable pellets which are a large proportion of the foundry’s input. Similarly, bronze castings for thrust plate machining undergo a sustainable recycling process. Machining coolants and cutting oils are also recycled.

Quality Control in GPM Manufacture

Being conscious of its responsibility to the environment and future generations, GPM has also been certified in accordance with ISO 14001:2015 Environmental Management Standards.

See GPM’s ISO 9001:2015 and ISO 14001:2015 certificates here.

Their quality management system makes use of statistical analyses to determine manufacturing process capability.

The stability of manufacturing processes is continuously monitored and managed via machine run charts. In line with their technology investment philosophy, they have recently invested in a 3 dimensional co-ordinate measurement machine.

This will increase productivity by means of faster first-off measurement as well as enabling expanded statistical sampling checks.